- Home

- About

- Product

- New

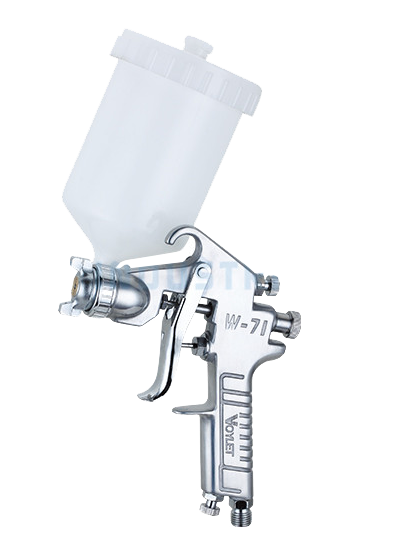

- Hvlp Spray Guns

- Heavy Duty Spray Guns

- Woodworking Low Pressure Spray Guns

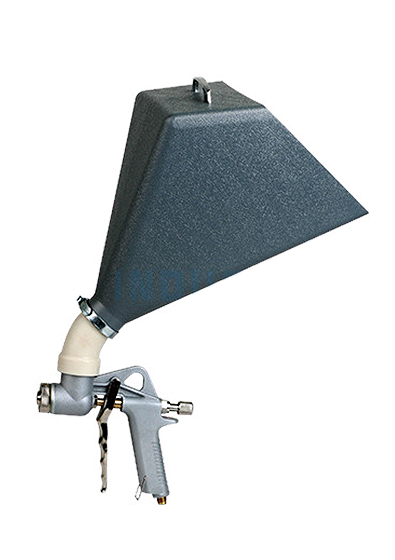

- Texture Paint Spray Guns

- Paraffin Guns(Washing Gun Series)

- Air Blowing Guns

- Sandblast Guns/Foam Guns

- Tyre Inflating Guns

- Water Guns & Grease Guns

- Automatic Spray Guns

- Air Brushes

- Paint Tanks

- Air Fittings & Accessories

- Spray Gun Kits

- Car Polish Machine

- More

- Airless Spray Gun

- News

- Download

- Contact

Search

Search

English

English 中文简体

中文简体 Deutsch

Deutsch Español

Español