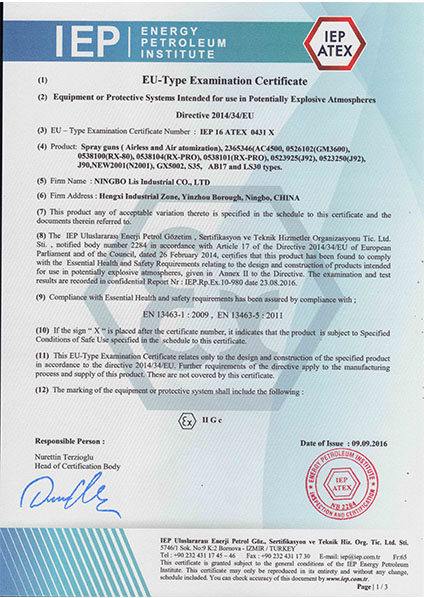

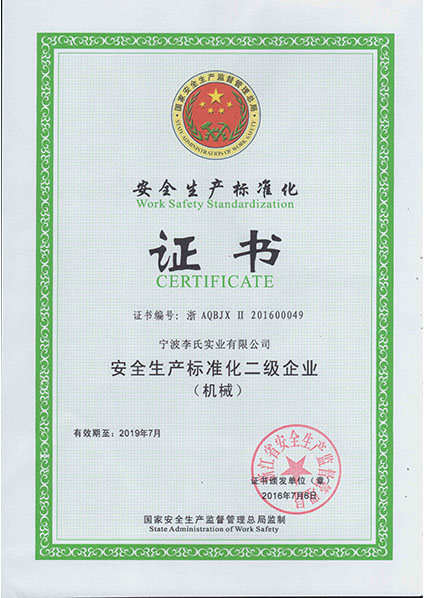

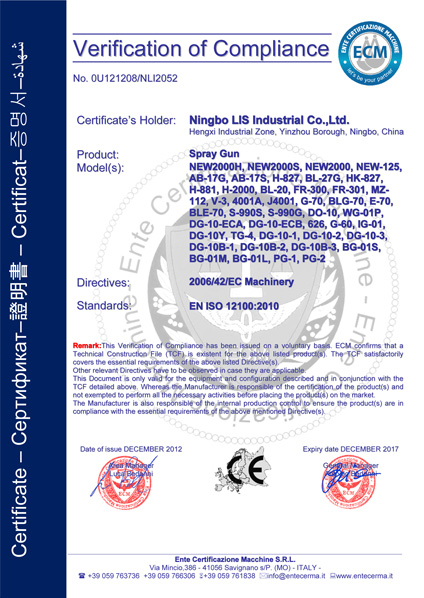

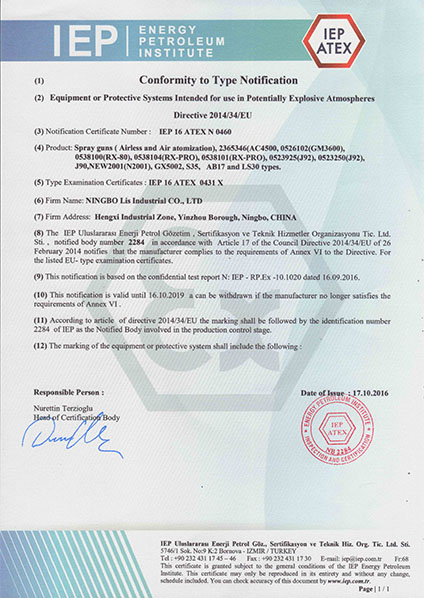

Ningbo Lis Industrial Co., Ltd is advaned China Us.Standard Manufacturers and Us.Standard factory. Our products have passed certificates of CE, GS, etc. Product quality is the key to gaining a larger share of the market. Lis has always been pursuing highest standards for product quality. We have a strong R& D team, in addition to OEM according to the drawings or samples provided by customers, we can also provide ODM and OEM services according to customer needs. By now, Lis has established a worldwide marketing and service network. Our products are widely sold into Europe, North America, Middle East, South Africa and East Asia, and developed a good business relationship in those countries and areas. Us.Standard customizable.

- Home

- About

- Product

- New

- Hvlp Spray Guns

- Heavy Duty Spray Guns

- Woodworking Low Pressure Spray Guns

- Texture Paint Spray Guns

- Paraffin Guns(Washing Gun Series)

- Air Blowing Guns

- Sandblast Guns/Foam Guns

- Tyre Inflating Guns

- Water Guns & Grease Guns

- Automatic Spray Guns

- Air Brushes

- Paint Tanks

- Air Fittings & Accessories

- Spray Gun Kits

- Car Polish Machine

- More

- Airless Spray Gun

- News

- Download

- Contact

Search

Search

English

English 中文简体

中文简体 Deutsche

Deutsche